Real-World Farm Fault Diagnostics

Explore detailed verified examples of fault detection, corrective actions, energy gains, and financial benefits across diverse locations worldwide and for various solar farm capacities.

Some cases have been identified using SmartHelio software. All faults mentioned are detectable with SmartHelio software.

Discover success stories

The following Table highlights success stories and the high benefit (value for money) of implementing diagnostic & analytics.

SmartHelio in partnership with Solarca-Analysis offers a high value business proposition to boost you farm profitability

| Case Location & Farm Size | Specific Fault | Corrective Action | Detection Method | Energy Gain Documented | Annual Money Gain (USD / EUR) | Confidence / Source |

|---|---|---|---|---|---|---|

| Egypt – 0.3 MW (C&I rooftop) | Curtailment / shutdowns | Operational adjustments per diagnostic | SmartHelio Fast Diagnostic (AC-only) | 7–10 % (~20–30 MWh / yr) | $2 000 – 7 000 / yr | SmartHelio 2024 |

| UK – 1 MWp | Multiple undetected faults | Systematic inspection protocols | SCADA + automated analytics | Up to 38 % loss recovery | €30 400 – 76 000 / yr | WJARR 2024 |

| Spain – 1 MW (Granada) | Seasonal soiling (~2.8 % loss) | Optimized summer clean schedule | Soiling + economic model | +3.6 % profit (~54 MWh) | €5 400 / yr | MPRA 105229 (2021) |

| Turkey – 1.6 MW | Hot spots & faulty connections | Repair of defective modules & connections | Thermal imaging + I-V traces | 16 % performance improvement (0.35 GWh / yr) | €28 000 – 70 000 / yr | ScienceDirect 2023 |

| Malaysia – 2 MW | Dust accumulation (4–8 g/m²) | Robotic cleaning (90–92 % eff.) | IR + production monitoring | 10–15 % yield gain | €35 200 – 88 000 / yr | Energy Reports 2023 |

| South Africa – 2 MW (mining C&I) | Soiling + O&M workflow gaps | SOP cleaning & preventive maintenance | O&M audit + RCA workflow | 3–7 % (~100 MWh) | $6 000 / yr | African PV Ops 2022 |

| Italy (Brindisi) – 2 MW (2 × 1 MW) | Aged inverters | Revamp → string inverters | Engineering audit | ≈ 5–7 % availability gain | $5 000 – 7 000 / yr | Renewable Energy Mag 2025 |

| Austria – 3.03 MW (2 plants) | Tracker faults, soiling | Predictive maintenance actions | SmartHelio AI (SCADA analytics) | ≈ 4 % (~120 MWh) | €12 000 / yr | SmartHelio × VERBUND 2024 |

| UK – 5 MW utility | Hotspots / string faults | Targeted module repairs | Drone thermography | 6–7 % production increase | ≈ €68 000 / yr | PowerFactors 2023 |

| France – 6.7 MW | Inverter communication failure | Comm repair & reset | SCADA log analysis | 8.2 % improvement | $17 700 / yr (est.) | Nature Energy 2023 |

| Pakistan – 8.79 MW | Module dust & degradation | Cleaning + replacement | SCADA + I-V curves | Up to 20 % yield recovery | $19 800 / yr (est.) | PMC 2023 |

| India – 11 MW (Block B) | Electrical & string underperformance | Predictive O&M correction | Real-time SCADA diagnostics | 10–15 % energy gain | €88 000 – 264 000 / yr | VHIVE 2023 |

| Multiple sites (6× plants ≤ 10 MW each) | Mixed faults (soiling, thermal, string) | Smart Decision Module (SDM) automated maintenance | AI predictive SCADA integration | Up to 16 % performance gain | €160 000 – 600 000 / yr (per 10 MW) | ScienceDirect 2024 |

| Multiple countries (218+ plants worldwide) | Soiling / MPPT inefficiencies | Prescriptive AI RCA & maintenance scheduling | Global fleet monitoring platform | 6–7 % avg production increase | €480 000 – 1.2 M / yr (total fleet) | SmartHelio Global Data 2024 |

| Italy – 10 MW (multi-site) | AC switch / inverter failure | Switch + inverter replacement | SCADA / sensor RCA | 4–12 % recovery to benchmark | $2 100 / yr (est.) | IEA-PVPS 2024 |

| North Africa (meta) – 10 MW (avg.) | Infrequent cleaning policy | Optimized cleaning schedule | Regional meta-analysis | 2–6 % (~240 MWh) | $14 000 / yr | Regional Study 2023 |

| Harrodsburg (Kentucky, USA) – 10 MW | Soiling (PR loss 6.3 %) | Brush + water cleaning after RCA | String-level measurements | > 12 % (~754 MWh / yr) | $18 858 / yr (@ $0.025 / kWh) | UKY Case Study 2021 |

Enhancing Solar Farm Performance Through Analysis

Faults identified by diagnostics & analytics and corrective actions implemented boosted energy output.

Sustainable Improvements via Targeted Diagnostics

Fault detection and resolution led to optimized energy production and system reliability.

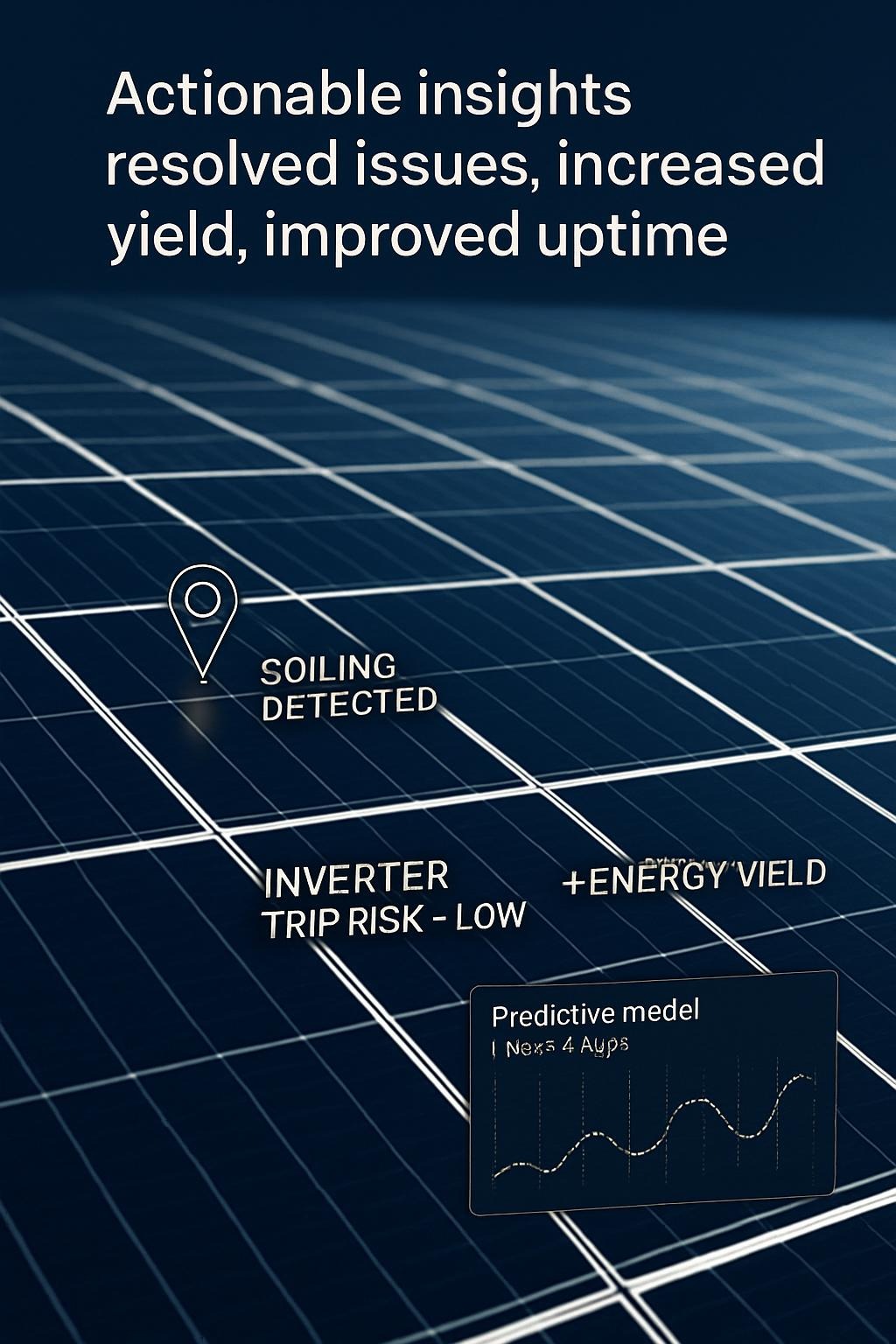

Driving Energy Efficiency in Solar Farms

actionable predictive insights and early corrective actions increases energy yield, and improved operational uptime.

Fault Detection Accuracy

SmartHelio software identifies faults swiftly, enabling targeted repairs that minimize downtime and energy loss. Solarca-Analysis will help you to achieve this goal

Corrective Action Implementation

The diagnostics & analytics guide precise interventions that restore optimal farm performance and boost energy output.

Energy Gain Results

Post-correction monitoring as shown in the previous Table indicates significant energy gains, (and financial gains) validating the effectiveness of diagnostic & analytics solutions.

Boost farm performance by identifying hidden losses.

Recover 5-10%+ energy annually

No new hardware required

SmartHelio leverages your existing data with advanced software

Solarca-Analysis will help you with onboarding and coordination

Typical assessments reveal fixable issues such as:

soiling, inverter faults, string problems, curtailment, and more

NOTE: Results vary based on farm condition, weather, grid constraints,

and repair turnaround time

Solarca-Analysis will also guide you through SmartHelio’s

free AI-powered diagnostic

Reach us via email, phone, WhatsApp – we respond promptly